Key points of double color mold design

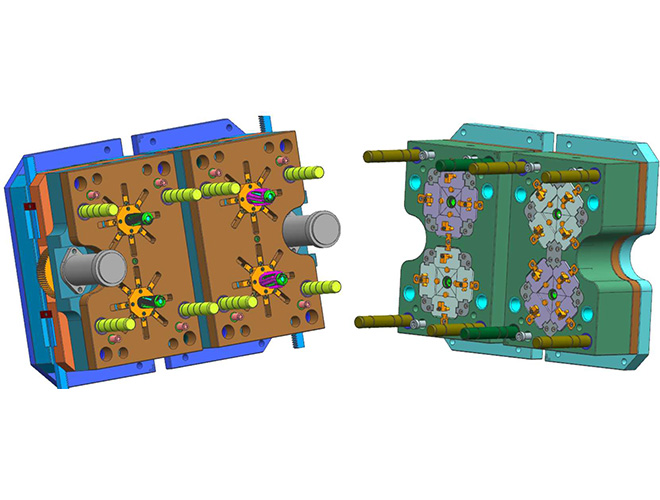

1. Guide sleeve of mold embryo guide post must be symmetrical up and down, and symmetric before and after mold to ensure that the mold can be closed after 180 rotation, the thickness of the formwork must be consistent, and the thickness tolerance of the formwork should be controlled within 0.05mm.

2. Product spacing must be based on the spacing of injection molding machine nozzle.

3. Two independent ejector systems with spring resetting for thimble plate

4. The two rear parting surfaces must be the same.

5. The direction of water transport must be on the side of heaven and earth, and the inlet and outlet of each circulating water must be on the same surface, do not water in the sky, the water in the ground side, because the back mold to rotate 180 degrees, pay attention to the mold size should not exceed the injection molding machine. The height out of the tank. Otherwise, no water can be delivered.

6. The product injected for the first time should be placed on the non-operating side, because the product should be rotated 180 degrees for the second time after the first injection molding, is turning to the operation side, easy to take the product.

7. The side lock must be on the four sides of the center of the mold, and the front and back molds are symmetric, otherwise when the back mold rotates 180, it cannot match with the front mold.