DFM REPORT

DFM means design for manufacturing, we will work on the 2D data, 3D data, and samples you provide preliminary analysis, through the material properties, product structure analysis, such as wall thickness, deformation, glue position, in advance Identify potential problems and put forward suggestions for improvement to make the product more manufacturable and at the lowest cost, the shortest time, of the highest quality manufacturing.

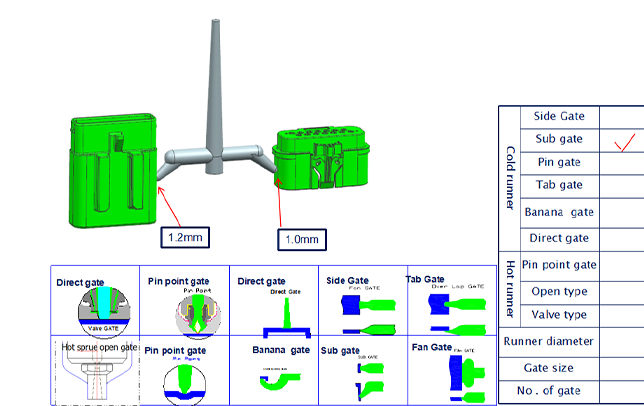

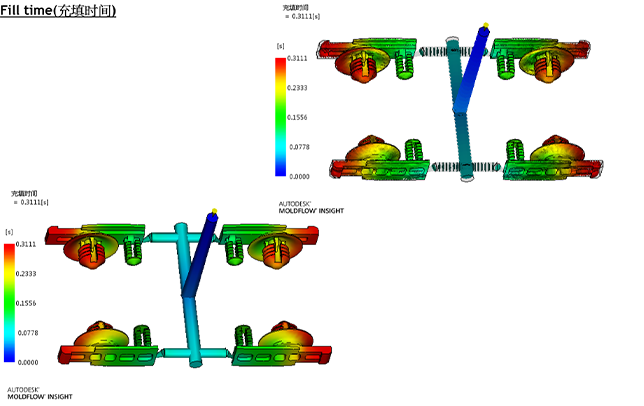

Mold Flow Analysis

Mold flow analysis through the computer simulation of injection molding simulation, some results, can help us early understanding of the defects in the injection molding process, through these results to improve the mold design scheme, avoid later mold modification, so as to save the mold development cycle.

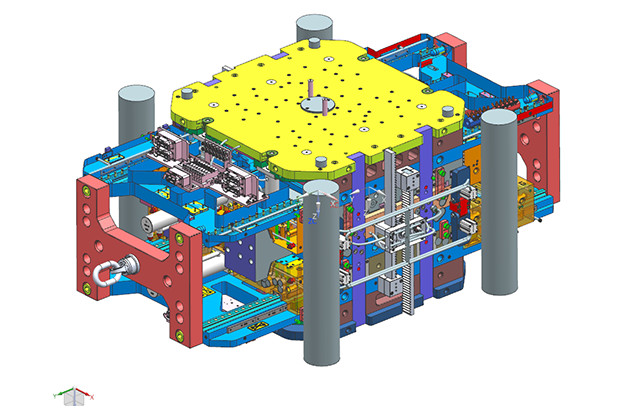

3D Design

According to the DFM report and mold flow analysis report, the engineer conducts the mold 3D design.

Mold design review

After the completion of 3D design, the project engineer organized relevant departments to discuss the 3D drawing file of the mold, systematically reviewed the mold design structure, parts manufacturing feasibility, mold assembly process, injection molding process and other aspects, and put forward suggestions for improvement.