Parts manufacturing

As an advanced mold manufacturer, with CNC milling, EDM discharge machining, grinding machine processing, slow line cutting processing and all processing capacity.Mold assembly

Before assembly, we should carefully study and analyze the general assembly drawing and part drawing to understand the role, characteristics and technical requirements of each part, determine the assembly benchmark, and finally fully achieve the quality indicators of products, mold action accuracy and technical requirements in the process of use.

Mold Testing

After the assembly of the mold, conduct relevant tests for the performance of the mold to ensure the operation of each system normal, during the test, we will record relevant injection parameters (such as mold temperature, melt temperature, injection pressure, firing rate, ejection pressure) and product injection defects, as a reference for mold improvement.

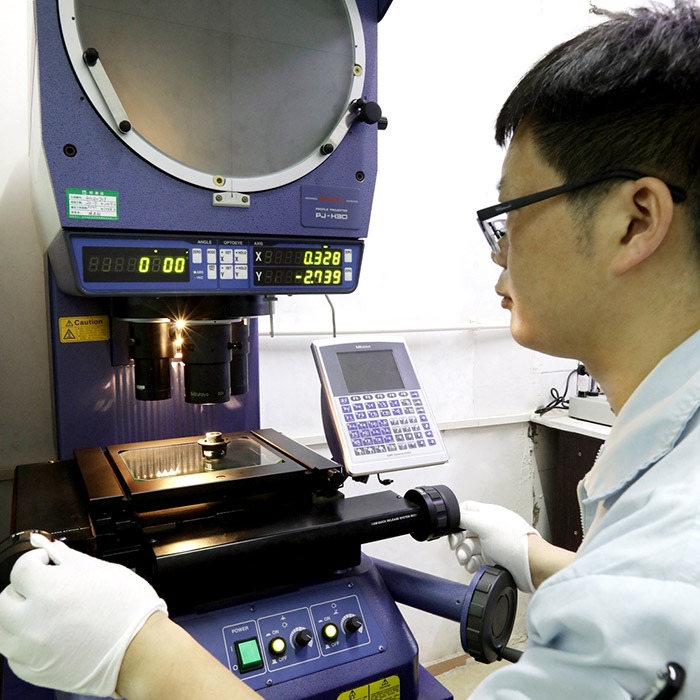

Sample Testing

For the sample shape, the test will be carried out 12H after the sample injection molding. The test content is as follows:

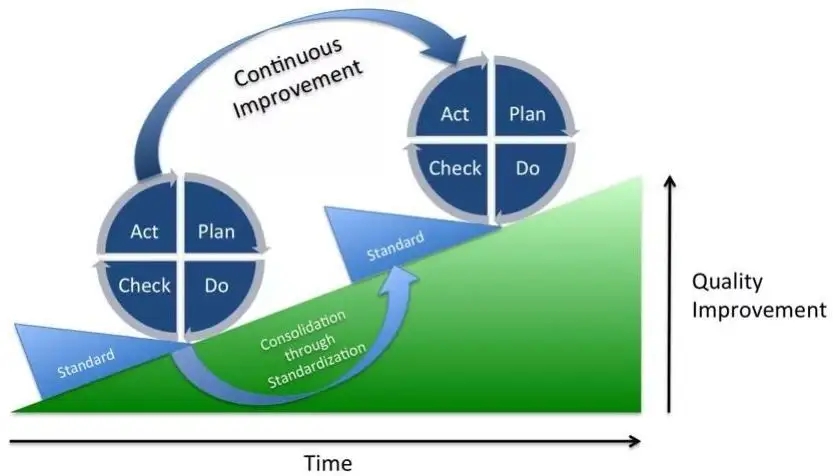

Continuous Improvement

When the T1 model trial is completed, the project engineer will convene a project summary meeting within 12 hours. review the problems in mold testing, product defects, product size, etc. And determine the modification plan countermeasures.