Connector, which usually refers to an electronic connector, that is, a device that connects two active devices and transmits current or signals.

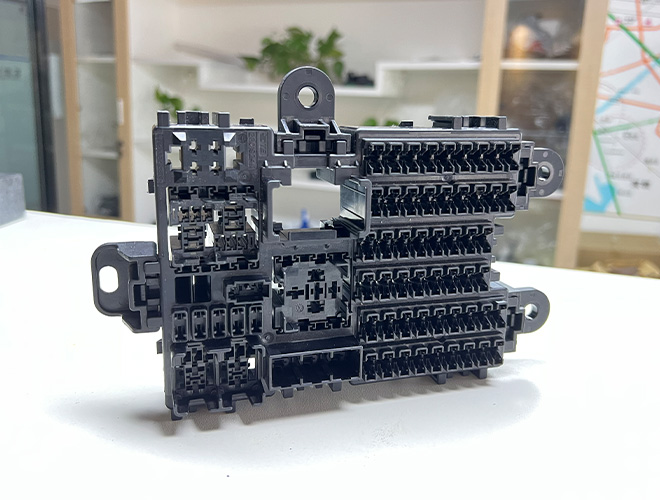

Connectors are divided into four types by shape: round connectors, rectangular connectors, bar connectors, and D-type connectors, circular and rectangular connectors are the most common! Connectors are widely used in automobile, electronics, electrical appliances, aviation and other industries.

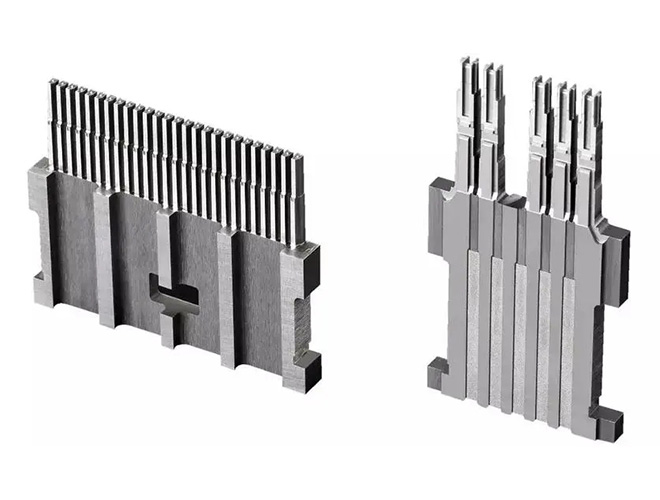

Yongzhen Molding in the connector mold manufacturing has more than ten years of history, in the automobile connector mold, electronic connector mold design and processing accumulated rich experience, mold parts tolerance within 0.005mm, product tolerance 0.02mm.